In the world of furniture manufacturing, ensuring quality control is essential to producing high-quality products that meet customer expectations. One effective tool that can help streamline the quality control process is a furniture quality control checklist. This checklist serves as a comprehensive guide for manufacturers to inspect and evaluate the quality of their products at various stages of production.

In this article, we will delve into the what, why, and how of furniture quality control checklists, as well as provide examples and tips for successful implementation.

What is a Furniture Quality Control Checklist?

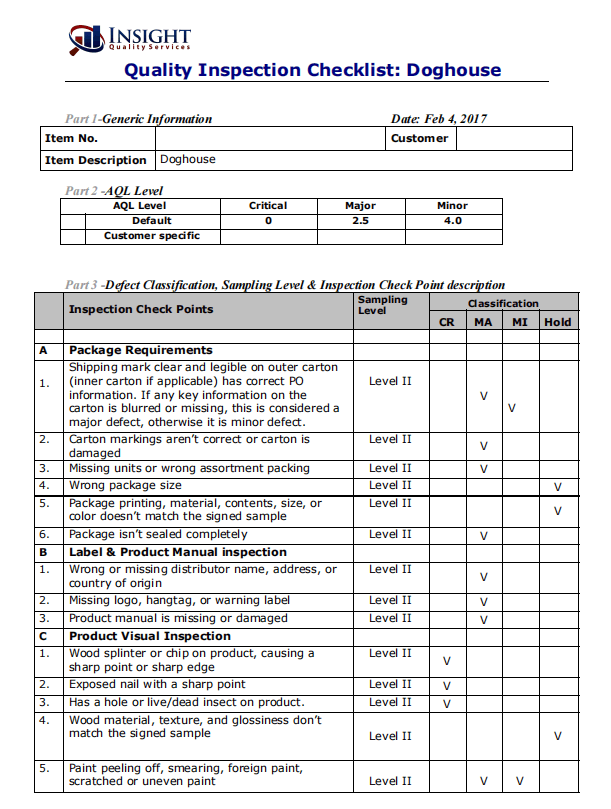

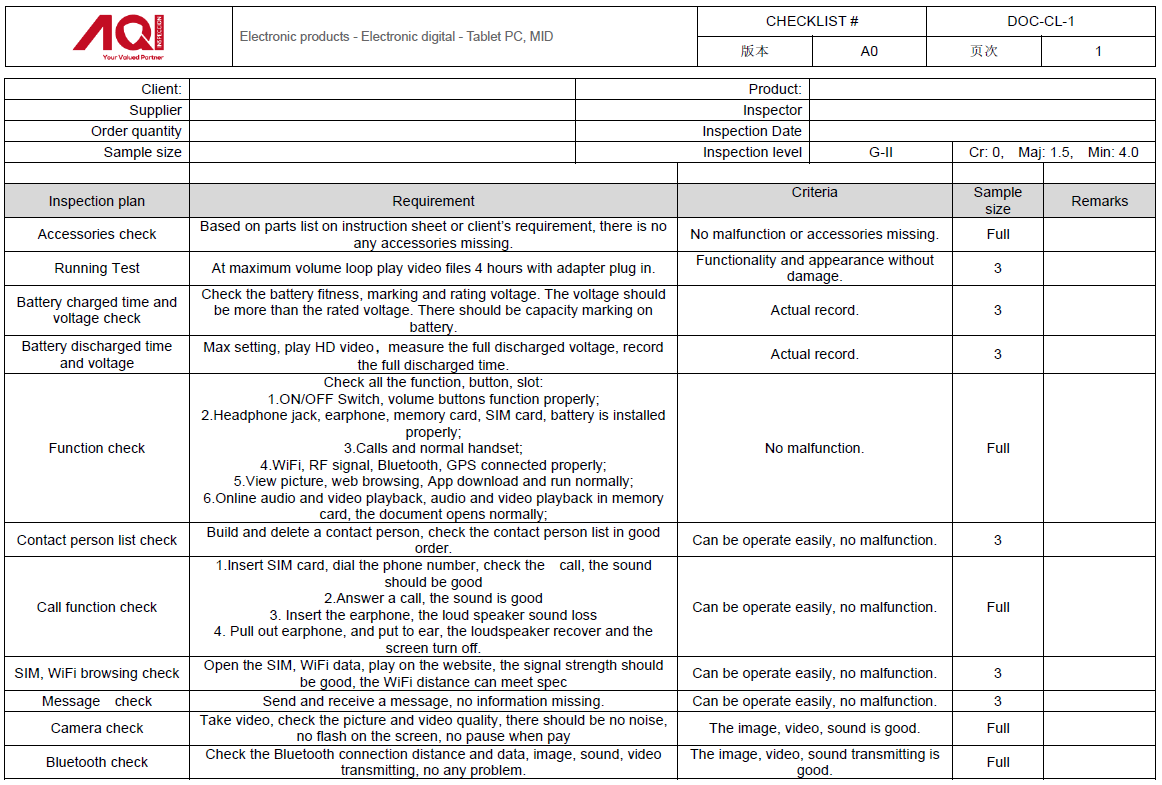

A furniture quality control checklist is a document that outlines the specific criteria and standards that furniture manufacturers need to adhere to in order to ensure that their products meet quality standards. This checklist typically includes a list of items or parameters that need to be inspected, such as material quality, construction, finishes, and overall aesthetics.

By using a checklist, manufacturers can systematically evaluate each piece of furniture to identify any defects or issues that need to be addressed before the product is released to the market.

Why Use a Furniture Quality Control Checklist?

There are several benefits to using a furniture quality control checklist. One of the main advantages is that it helps manufacturers maintain consistency in their quality control processes. By having a standardized checklist, all inspectors can follow the same criteria when evaluating products, ensuring that every piece of furniture is assessed in a systematic and objective manner. Additionally, a checklist can help manufacturers identify recurring issues or trends in product quality, allowing them to implement corrective actions to improve their processes.

How to Create a Furniture Quality Control Checklist

Creating a furniture quality control checklist involves several key steps. First, manufacturers need to identify the critical quality control points in their production process, such as raw material inspection, assembly, finishing, and packaging. Next, they should define the specific criteria for each quality control point, such as acceptable tolerances for dimensions, color consistency, and surface finish.

Once the criteria are established, manufacturers can design a checklist template that includes all the inspection items and leave space for inspectors to record their findings.

- Identify critical quality control points: Determine the key stages in the production process that require inspection.

- Define specific criteria: Establish clear standards for each quality control point to ensure consistency.

- Create checklist template: Design a checklist that includes all inspection items and allows for documentation.

- Train inspectors: Provide training to inspectors on how to use the checklist effectively and interpret the criteria.

Examples of Furniture Quality Control Checklists

To give you a better idea of what a furniture quality control checklist looks like, here are some examples of common inspection items that may be included in the checklist:

1. Material quality inspection

2. Dimensional accuracy check

3. Finish and color consistency evaluation

4. Hardware and fittings inspection

5. Structural integrity assessment

6. Packaging and labeling review

Tips for Successful Implementation of Furniture Quality Control Checklist

Implementing a furniture quality control checklist effectively requires careful planning and attention to detail. Here are some tips to help you ensure the success of your quality control process:

1. Regularly update the checklist to reflect changes in product specifications or quality standards.

2. Conduct regular training sessions for inspectors to ensure they understand the criteria and how to use the checklist.

3. Use the checklist as a tool for continuous improvement by analyzing inspection data and identifying areas for enhancement.

4. Involve key stakeholders, such as production managers and quality control supervisors, in the development and review of the checklist.

5. Encourage feedback from inspectors on the usability and effectiveness of the checklist to make necessary adjustments.

By following these tips and incorporating a furniture quality control checklist into your manufacturing process, you can enhance the quality of your products and ultimately improve customer satisfaction.